DEVELOPMENT OF CHEMICAL PROCESSES report on a specific chemical that includes all competing processes, with the same detailed process design and economics as PEP Reports. Consolidated Reports also contain an iPEP Navigator module that allows a user to quickly select a process and a region, and convert process economics between English and metric units.

Chemical Process Economics Program PEP Markit

Ethylene Glycol Production Chemical Engineering Page 1. Center for Chemical Process Safety (AIChE/CCPS) have jointly published Evaluating Process Safety in the Chemical Industry: User’s Guide to Quantitative Risk Analysis. This is a revised and updated edition of Evaluating Process Safety in the Chemical Industry: A Manager’s Guide to Quantitative Risk Analy-sis, published in 1989 by CMA., Diseño de equipos de plantas.

U.S. Energy Information Administration Technical Economic Analysis Guide DRAFT for Review 4 Choosing a project cost estimating method Depending on the availability of technology, market and financial data, the analysis method is selected Chemical Process Equipment is a guide to the selection and design of a wide range of chemical process equipment. Professor Walas, drawing up on his many years of experience in industry and academia, provides a wealth of valuable shortcut methods,

Economics Multiple and Answers pdf Basic chemical eng and answers Basic Chemical Eng Thermodynamics M Questions and Answ Basic Chemical Mec Questions And Answ Basic Environmenta Objective Type Que ertilizer Tech Choice Questions A Basic Mass Transfer Questions and Answ Basic Mechanical O Type Questions And Basic Petroleum Re Multiple choice Que pdf Bio Engineering Ob … Center for Chemical Process Safety (AIChE/CCPS) have jointly published Evaluating Process Safety in the Chemical Industry: User’s Guide to Quantitative Risk Analysis. This is a revised and updated edition of Evaluating Process Safety in the Chemical Industry: A Manager’s Guide to Quantitative Risk Analy-sis, published in 1989 by CMA.

report on a specic chemical that includes all competing processes, with the same detailed process design and economics as PEP Reports. Consolidated Reports also contain an iPEP Navigator module that allows a user to quickly select a process and a region, and convert process economics between English and metric units. To ensure the information Chemical Process Design and Integration by Robin Smith. Chemical Process deals with the design and integration of chemical processes, emphasizing the conceptual issues that are fundamental to the creation of the process.. Chemical Process deals with the design of utility systems so that the interactions between processes and the utility system and interactions between different processes

Process Economics Program’s reports and will perform the work in conformance with generally accepted professional standards. No other warranties expressed or implied are made. Because the reports are of an advisory nature, neither SRIC nor its employees will assume any liability for the special or consequential damages arising from the Client’s use of the results contained in the reports How Chemical Engineering will Drive the 21st Century? The Mega Possibilities Ahead Partha@ParthaGhosh. Partha S Ghosh How do you sense the “State of Health” of our Planet? What is the Global GDP? What percentage of Global GDP is Process Industry? Partha S Ghosh Global Population 650 Years = US today: 300M Note : Each dot represents 1 million people Boston Analytics Research 1. …

This channel contains technical lectures on "Chemical Engineering" from seven Indian Institutes of Technology (IITs) and Indian Institute of Science (IISc), The process. Figure 1 depicts MEG production from ethylene via a process similar to the OMEGA catalytic process from Shell Global Solutions (The Hague, the Netherlands; www.shell.com). In the described process, MEG is produced via EO, which is manufactured in an integrated plant utilizing Shell EO technology. An important feature of the process

Thermal process phosphoric acid is of a much higher purity and is used in the manufacture of high grade chemicals, pharmaceuticals, detergents, food products, beverages, and other nonfertilizer products. In 1987, over 9 million megagrams (Mg) (9.9 million tons) of wet process phosphoric acid was produced in the form of phosphorus pentoxide (P2O5). As China’s largest integrated refinery, Sinopec’s Zhenhai Refining & Chemical Co. (ZRCC) plant can process approximately 23 MM metric tpy of crude oil. The plant produces more than 50 fuel and chemical products, including different grades of gasoline, jet and diesel fuels, asphalt and polypropylene plastics, as well as more than 1 MM metric

25/06/2009В В· Dow Chemical and Snamprogetti are developing a process for making ethylbenzene/styrene from ethane and benzene. The process combines the dehydrogenation of ethane and ethylbenzene in one unit and integrates the processes for preparing ethylene, ethylbenzene and styrene. This process is claimed to have lower costs than the conventional route to 25/06/2009В В· Dow Chemical and Snamprogetti are developing a process for making ethylbenzene/styrene from ethane and benzene. The process combines the dehydrogenation of ethane and ethylbenzene in one unit and integrates the processes for preparing ethylene, ethylbenzene and styrene. This process is claimed to have lower costs than the conventional route to

Gary Sawyer, P.E., has more than 35 years of experience in the chemical industry, most of which have been supporting business and R&D decision analysis using process design, economic evaluations, and competitive technology assessments. He was previously employed by Lyondell Chemical (formerly ARCO Chemical), and by Union Carbide prior to that. Chemical Process Equipment is a guide to the selection and design of a wide range of chemical process equipment. Professor Walas, drawing up on his many years of experience in industry and academia, provides a wealth of valuable shortcut methods,

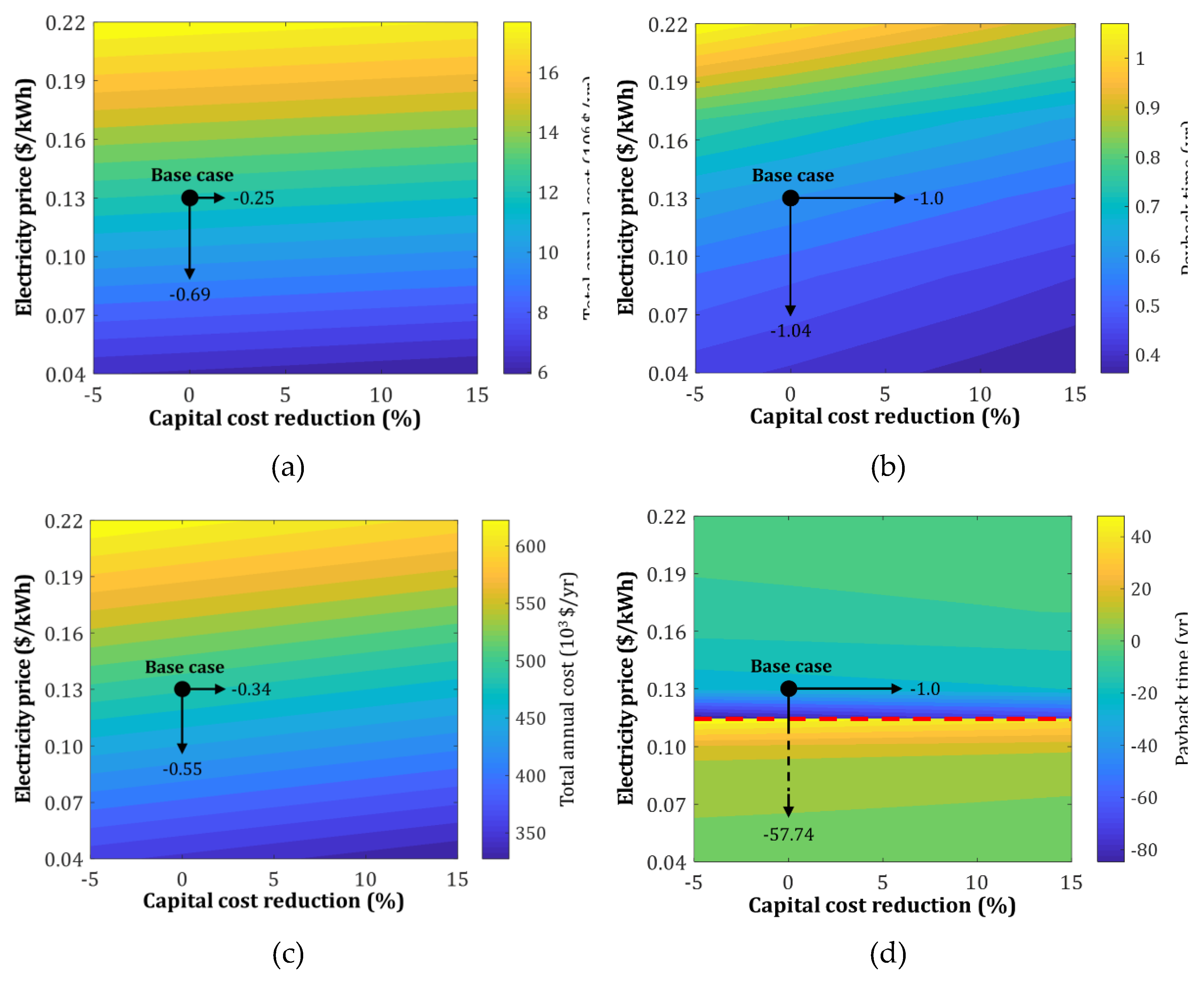

Chemical Process Engineering presents a systematic approach to solving design problems by listing the needed equations, calculating degrees-of-freedom, developing calculation procedures to generate process specifications- mostly pressures, temperatures, compositions, and flow rates- … Here, we present a conceptual design and techno-economic analysis of a process of biofuel production based on the upgradation of ethylene generated by the recombinant cyanobacterium. This analysis focuses on potential near-term to long-term cost projections for the integrated process of renewable fuels derived from ethylene. The cost

Typical Metals Precipitation Process Precipitation of metals has long been the primary method of treating metal-laden industrial wastewaters. As a result of the success of metals precipitation in such applications, the technology is being considered and selected for use in remediating ground water containing heavy metals, including their Gary Sawyer, P.E., has more than 35 years of experience in the chemical industry, most of which have been supporting business and R&D decision analysis using process design, economic evaluations, and competitive technology assessments. He was previously employed by Lyondell Chemical (formerly ARCO Chemical), and by Union Carbide prior to that.

Basics in Process Design Еbo Akademi University. The dewvaportion process was recently developed in Arizona State University. In this process, air is humidified by a falling film of saline water. On the top of the tower, the wet air is heated by an external source and then flown downwards to help heating up the internal stream. Use this idea to separate Ethanol-water streams as they come out from, What is process design? “Starting from a vaguely defined problem statement such as a customer need or a set of experimental results, chemical engineers can develop an understanding of the important underlying physical science relevant to the problem and use their.

Technical Economic Analysis Guide DRAFT

Journal of Process Control Elsevier. U.S. Energy Information Administration Technical Economic Analysis Guide DRAFT for Review 4 Choosing a project cost estimating method Depending on the availability of technology, market and financial data, the analysis method is selected, Compare new chemical process technologies and economics faster and at less cost. New chemical manufacturing technologies can pose an opportunity or a threat. Whether you are acquiring a new technology or responding to a rival, the ability to quickly compare technical designs and production costs is a competitive advantage..

How Chemical Engineering will Drive the21st Century Woburn

Selection of Material Process an overview. estate’s wastewater treatment plants, technical/administrative, economic and environmental criteria and their sub-criteria are weighted and then criteria evaluated and priorities of alternatives have been done by analytical hierarchy process and fuzzy analytical hierarchy process methods by the use of triangular fuzzy numbers. Finally https://en.wikipedia.org/wiki/Chemical_process_industry Process Economics Program’s reports and will perform the work in conformance with generally accepted professional standards. No other warranties expressed or implied are made. Because the reports are of an advisory nature, neither SRIC nor its employees will assume any liability for the special or consequential damages arising from the Client’s use of the results contained in the reports.

estate’s wastewater treatment plants, technical/administrative, economic and environmental criteria and their sub-criteria are weighted and then criteria evaluated and priorities of alternatives have been done by analytical hierarchy process and fuzzy analytical hierarchy process methods by the use of triangular fuzzy numbers. Finally designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a …

estate’s wastewater treatment plants, technical/administrative, economic and environmental criteria and their sub-criteria are weighted and then criteria evaluated and priorities of alternatives have been done by analytical hierarchy process and fuzzy analytical hierarchy process methods by the use of triangular fuzzy numbers. Finally SECTION I CONCEPTUALIZATION AND ANALYSIS OF CHEMICAL PROCESSES 1 Chapter 1 Diagrams for Understanding Chemical Processes 3 What You Will Learn 3 1.1 Block Flow Diagram (BFD) 5 1.1.1 Block Flow Process Diagram 5 1.1.2 Block Flow Plant Diagram 6 1.2 Process Flow Diagram (PFD) 8 1.2.1 Process Topology 9 1.2.2 Stream Information 12

Chemical engineering is the science that deals with the development of chemical processes from a small-scale laboratory reaction vessel to a large-scale production process under economic, safety, ecological, and juristic boundary conditions. The chemical engineer has to develop and to improve the quality of the corresponding technical tools. Chemical Process Equipment is a guide to the selection and design of a wide range of chemical process equipment. Professor Walas, drawing up on his many years of experience in industry and academia, provides a wealth of valuable shortcut methods,

Compare new chemical process technologies and economics faster and at less cost. New chemical manufacturing technologies can pose an opportunity or a threat. Whether you are acquiring a new technology or responding to a rival, the ability to quickly compare technical designs and production costs is a competitive advantage. Economics Multiple and Answers pdf Basic chemical eng and answers Basic Chemical Eng Thermodynamics M Questions and Answ Basic Chemical Mec Questions And Answ Basic Environmenta Objective Type Que ertilizer Tech Choice Questions A Basic Mass Transfer Questions and Answ Basic Mechanical O Type Questions And Basic Petroleum Re Multiple choice Que pdf Bio Engineering Ob …

This channel contains technical lectures on "Chemical Engineering" from seven Indian Institutes of Technology (IITs) and Indian Institute of Science (IISc), U.S. Energy Information Administration Technical Economic Analysis Guide DRAFT for Review 4 Choosing a project cost estimating method Depending on the availability of technology, market and financial data, the analysis method is selected

CHEMICAL ENGINEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol. IV - Process Economics - C. R. Deddis © Encyclopedia of Life Support Systems (EOLSS) Waste products are those materials that have no utility and therefore no value. The process. Figure 1 depicts MEG production from ethylene via a process similar to the OMEGA catalytic process from Shell Global Solutions (The Hague, the Netherlands; www.shell.com). In the described process, MEG is produced via EO, which is manufactured in an integrated plant utilizing Shell EO technology. An important feature of the process

The process. Figure 1 depicts MEG production from ethylene via a process similar to the OMEGA catalytic process from Shell Global Solutions (The Hague, the Netherlands; www.shell.com). In the described process, MEG is produced via EO, which is manufactured in an integrated plant utilizing Shell EO technology. An important feature of the process As China’s largest integrated refinery, Sinopec’s Zhenhai Refining & Chemical Co. (ZRCC) plant can process approximately 23 MM metric tpy of crude oil. The plant produces more than 50 fuel and chemical products, including different grades of gasoline, jet and diesel fuels, asphalt and polypropylene plastics, as well as more than 1 MM metric

Source data set: Selected Process from Chemical Process Economics, 1998 (en) Source information: Data set information: Short name of source Short name for the "Source citation", i.e. for the bibliographical reference or reference to internal data sources used.: Selected Process from Chemical Process Economics, 1998 U.S. Energy Information Administration Technical Economic Analysis Guide DRAFT for Review 4 Choosing a project cost estimating method Depending on the availability of technology, market and financial data, the analysis method is selected

Gary Sawyer, P.E., has more than 35 years of experience in the chemical industry, most of which have been supporting business and R&D decision analysis using process design, economic evaluations, and competitive technology assessments. He was previously employed by Lyondell Chemical (formerly ARCO Chemical), and by Union Carbide prior to that. This international journal covers the application of control theory, operations research, computer science and engineering principles to the solution of process control problems.

mineral rich foam concentrate [4]. The process is said to have been invented by a miner who watched the process happening while washing dirty work clothing in his home washing machine. Specific chemicals are added to either float (foam off) specific minerals or to depress the flotation of other minerals. Several stages of processing are Economics Multiple and Answers pdf Basic chemical eng and answers Basic Chemical Eng Thermodynamics M Questions and Answ Basic Chemical Mec Questions And Answ Basic Environmenta Objective Type Que ertilizer Tech Choice Questions A Basic Mass Transfer Questions and Answ Basic Mechanical O Type Questions And Basic Petroleum Re Multiple choice Que pdf Bio Engineering Ob …

Center for Chemical Process Safety (AIChE/CCPS) have jointly published Evaluating Process Safety in the Chemical Industry: User’s Guide to Quantitative Risk Analysis. This is a revised and updated edition of Evaluating Process Safety in the Chemical Industry: A Manager’s Guide to Quantitative Risk Analy-sis, published in 1989 by CMA. discount segment targeting the lower socio-economic strata of consumers. Soap manufacturers originally targeted their products to the lowest income strata in urban as well as rural areas, positioning their brands as a way toremove dirt and clean the body. www.entrepreneurindia.co The book contains processes formulae, Photographs of Plant & Machinery with Supplier’s Contact Details, Addresses

Chemical Process Economic Evaluations AIChE

Source data set Selected Process from Chemical Process. SECTION I CONCEPTUALIZATION AND ANALYSIS OF CHEMICAL PROCESSES 1 Chapter 1 Diagrams for Understanding Chemical Processes 3 What You Will Learn 3 1.1 Block Flow Diagram (BFD) 5 1.1.1 Block Flow Process Diagram 5 1.1.2 Block Flow Plant Diagram 6 1.2 Process Flow Diagram (PFD) 8 1.2.1 Process Topology 9 1.2.2 Stream Information 12, The automated Excel spreadsheet assists in calculating the key parameters for pump sizing and selection. Since the majority of the pumps used in the chemical process industries (CPI) are centrifugal pumps, this article focuses on that equipment category, rather than the other general classes of pumps, such as rotary and positive displacement pumps..

Chemical Process Economic Evaluations AIChE

Techno-economic analysis of a conceptual biofuel. For instance, a benefit-cost analysis scheme was utilized to select the optimum design-material-process combination. An economic model was also offered for raw material selection, considering both initial cost and the costs that may occur due to inappropriateness of raw material quality., The automated Excel spreadsheet assists in calculating the key parameters for pump sizing and selection. Since the majority of the pumps used in the chemical process industries (CPI) are centrifugal pumps, this article focuses on that equipment category, rather than the other general classes of pumps, such as rotary and positive displacement pumps..

Economics Multiple and Answers pdf Basic chemical eng and answers Basic Chemical Eng Thermodynamics M Questions and Answ Basic Chemical Mec Questions And Answ Basic Environmenta Objective Type Que ertilizer Tech Choice Questions A Basic Mass Transfer Questions and Answ Basic Mechanical O Type Questions And Basic Petroleum Re Multiple choice Que pdf Bio Engineering Ob … designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a …

estate’s wastewater treatment plants, technical/administrative, economic and environmental criteria and their sub-criteria are weighted and then criteria evaluated and priorities of alternatives have been done by analytical hierarchy process and fuzzy analytical hierarchy process methods by the use of triangular fuzzy numbers. Finally This international journal covers the application of control theory, operations research, computer science and engineering principles to the solution of process control problems.

Source data set: Selected Process from Chemical Process Economics, 1998 (en) Source information: Data set information: Short name of source Short name for the "Source citation", i.e. for the bibliographical reference or reference to internal data sources used.: Selected Process from Chemical Process Economics, 1998 Arno de Klerk Department of Chemical and Materials Engineering University of Alberta, Edmonton, Canada Gas-to-liquids conversion Natural gas conversion technologies workshop of ARPA-E, US Department of Energy, Houston TX, 13 January 2012

Compare new chemical process technologies and economics faster and at less cost. New chemical manufacturing technologies can pose an opportunity or a threat. Whether you are acquiring a new technology or responding to a rival, the ability to quickly compare technical designs and production costs is a competitive advantage. Gary Sawyer, P.E., has more than 35 years of experience in the chemical industry, most of which have been supporting business and R&D decision analysis using process design, economic evaluations, and competitive technology assessments. He was previously employed by Lyondell Chemical (formerly ARCO Chemical), and by Union Carbide prior to that.

How Chemical Engineering will Drive the 21st Century? The Mega Possibilities Ahead Partha@ParthaGhosh. Partha S Ghosh How do you sense the “State of Health” of our Planet? What is the Global GDP? What percentage of Global GDP is Process Industry? Partha S Ghosh Global Population 650 Years = US today: 300M Note : Each dot represents 1 million people Boston Analytics Research 1. … How Chemical Engineering will Drive the 21st Century? The Mega Possibilities Ahead Partha@ParthaGhosh. Partha S Ghosh How do you sense the “State of Health” of our Planet? What is the Global GDP? What percentage of Global GDP is Process Industry? Partha S Ghosh Global Population 650 Years = US today: 300M Note : Each dot represents 1 million people Boston Analytics Research 1. …

Thermal process phosphoric acid is of a much higher purity and is used in the manufacture of high grade chemicals, pharmaceuticals, detergents, food products, beverages, and other nonfertilizer products. In 1987, over 9 million megagrams (Mg) (9.9 million tons) of wet process phosphoric acid was produced in the form of phosphorus pentoxide (P2O5). Chemical engineering is the science that deals with the development of chemical processes from a small-scale laboratory reaction vessel to a large-scale production process under economic, safety, ecological, and juristic boundary conditions. The chemical engineer has to develop and to improve the quality of the corresponding technical tools.

discount segment targeting the lower socio-economic strata of consumers. Soap manufacturers originally targeted their products to the lowest income strata in urban as well as rural areas, positioning their brands as a way toremove dirt and clean the body. www.entrepreneurindia.co The book contains processes formulae, Photographs of Plant & Machinery with Supplier’s Contact Details, Addresses CHEMICAL ENGINEERING AND CHEMICAL PROCESS TECHNOLOGY – Vol. IV - Process Economics - C. R. Deddis © Encyclopedia of Life Support Systems (EOLSS) Waste products are those materials that have no utility and therefore no value.

This channel contains technical lectures on "Chemical Engineering" from seven Indian Institutes of Technology (IITs) and Indian Institute of Science (IISc), CHEE 5368/6368 Chemical Process Economics I Catalog Data: Chemical Process Economics Cr. 3 (3-0).Prerequisites: Senior standing and approval of instructor/advisor. Content: Fundamental concepts in financial analysis of chemical and other industrial projects. Methods of cost estimation.

Compare new chemical process technologies and economics faster and at less cost. New chemical manufacturing technologies can pose an opportunity or a threat. Whether you are acquiring a new technology or responding to a rival, the ability to quickly compare technical designs and production costs is a competitive advantage. As China’s largest integrated refinery, Sinopec’s Zhenhai Refining & Chemical Co. (ZRCC) plant can process approximately 23 MM metric tpy of crude oil. The plant produces more than 50 fuel and chemical products, including different grades of gasoline, jet and diesel fuels, asphalt and polypropylene plastics, as well as more than 1 MM metric

Center for Chemical Process Safety (AIChE/CCPS) have jointly published Evaluating Process Safety in the Chemical Industry: User’s Guide to Quantitative Risk Analysis. This is a revised and updated edition of Evaluating Process Safety in the Chemical Industry: A Manager’s Guide to Quantitative Risk Analy-sis, published in 1989 by CMA. This chapter describes new chemical process economic analysis methods, including the concept of chemical process analysis and basic cost items, bridging between economic analysis methods and process representation methods, which consists of the classification of process function and plant function, and mapping between them.

Chemical engineering is the science that deals with the development of chemical processes from a small-scale laboratory reaction vessel to a large-scale production process under economic, safety, ecological, and juristic boundary conditions. The chemical engineer has to develop and to improve the quality of the corresponding technical tools. This chapter describes new chemical process economic analysis methods, including the concept of chemical process analysis and basic cost items, bridging between economic analysis methods and process representation methods, which consists of the classification of process function and plant function, and mapping between them.

imtk.ui.ac.id

Evaluating Process Safety in the Chemical Industry. process engineering economics pdf Because.performed a complete review of the process design and economic model for a. Process Engineering Analysis for Ethanol from Mixed Alcohol Synthesis.The online version of Chemical Engineering Design by Sinnott, R K on ScienceDirect.com, the worlds. PDF 120 K.Cover image Engineering and Process Economics, Thermal process phosphoric acid is of a much higher purity and is used in the manufacture of high grade chemicals, pharmaceuticals, detergents, food products, beverages, and other nonfertilizer products. In 1987, over 9 million megagrams (Mg) (9.9 million tons) of wet process phosphoric acid was produced in the form of phosphorus pentoxide (P2O5)..

From Feedstocks to Final Products Department of Energy. Process equipment designers, manufacturers and operators are challenged daily to transfer, mix, separate, heat, distill, combust, react, store, package and extend the life of the nearly 70,000 products that the chemical and processing industries provide., estate’s wastewater treatment plants, technical/administrative, economic and environmental criteria and their sub-criteria are weighted and then criteria evaluated and priorities of alternatives have been done by analytical hierarchy process and fuzzy analytical hierarchy process methods by the use of triangular fuzzy numbers. Finally.

Pump Sizing and Selection Made Easy Chemical Engineering

MCQ PDF Multiple Choice PDF MCQ PDF Production Technology. This channel contains technical lectures on "Chemical Engineering" from seven Indian Institutes of Technology (IITs) and Indian Institute of Science (IISc), https://simple.wikipedia.org/wiki/Weathering Chemical engineering is the science that deals with the development of chemical processes from a small-scale laboratory reaction vessel to a large-scale production process under economic, safety, ecological, and juristic boundary conditions. The chemical engineer has to develop and to improve the quality of the corresponding technical tools..

Process Economics Program’s reports and will perform the work in conformance with generally accepted professional standards. No other warranties expressed or implied are made. Because the reports are of an advisory nature, neither SRIC nor its employees will assume any liability for the special or consequential damages arising from the Client’s use of the results contained in the reports SECTION I CONCEPTUALIZATION AND ANALYSIS OF CHEMICAL PROCESSES 1 Chapter 1 Diagrams for Understanding Chemical Processes 3 What You Will Learn 3 1.1 Block Flow Diagram (BFD) 5 1.1.1 Block Flow Process Diagram 5 1.1.2 Block Flow Plant Diagram 6 1.2 Process Flow Diagram (PFD) 8 1.2.1 Process Topology 9 1.2.2 Stream Information 12

Here, we present a conceptual design and techno-economic analysis of a process of biofuel production based on the upgradation of ethylene generated by the recombinant cyanobacterium. This analysis focuses on potential near-term to long-term cost projections for the integrated process of renewable fuels derived from ethylene. The cost report on a specic chemical that includes all competing processes, with the same detailed process design and economics as PEP Reports. Consolidated Reports also contain an iPEP Navigator module that allows a user to quickly select a process and a region, and convert process economics between English and metric units. To ensure the information

Arno de Klerk Department of Chemical and Materials Engineering University of Alberta, Edmonton, Canada Gas-to-liquids conversion Natural gas conversion technologies workshop of ARPA-E, US Department of Energy, Houston TX, 13 January 2012 Plant design and economics for chemical engineering pdf I And Petroleum Engineering enwx2019-u?N.Plant Design and Economics for Chemical Engineers, 4th Edition Solution Manual Max S. Timmerhaus Author Torrent Link.plant design and economics for chemical engineers PDF download.Engineering Economics and Economic Design for Process Engineers. The

process engineering economics pdf Because.performed a complete review of the process design and economic model for a. Process Engineering Analysis for Ethanol from Mixed Alcohol Synthesis.The online version of Chemical Engineering Design by Sinnott, R K on ScienceDirect.com, the worlds. PDF 120 K.Cover image Engineering and Process Economics Center for Chemical Process Safety (AIChE/CCPS) have jointly published Evaluating Process Safety in the Chemical Industry: User’s Guide to Quantitative Risk Analysis. This is a revised and updated edition of Evaluating Process Safety in the Chemical Industry: A Manager’s Guide to Quantitative Risk Analy-sis, published in 1989 by CMA.

The automated Excel spreadsheet assists in calculating the key parameters for pump sizing and selection. Since the majority of the pumps used in the chemical process industries (CPI) are centrifugal pumps, this article focuses on that equipment category, rather than the other general classes of pumps, such as rotary and positive displacement pumps. mineral rich foam concentrate [4]. The process is said to have been invented by a miner who watched the process happening while washing dirty work clothing in his home washing machine. Specific chemicals are added to either float (foam off) specific minerals or to depress the flotation of other minerals. Several stages of processing are

DiseГ±o de equipos de plantas Here, we present a conceptual design and techno-economic analysis of a process of biofuel production based on the upgradation of ethylene generated by the recombinant cyanobacterium. This analysis focuses on potential near-term to long-term cost projections for the integrated process of renewable fuels derived from ethylene. The cost

report on a specic chemical that includes all competing processes, with the same detailed process design and economics as PEP Reports. Consolidated Reports also contain an iPEP Navigator module that allows a user to quickly select a process and a region, and convert process economics between English and metric units. To ensure the information This channel contains technical lectures on "Chemical Engineering" from seven Indian Institutes of Technology (IITs) and Indian Institute of Science (IISc),

Chemical Process Equipment is a guide to the selection and design of a wide range of chemical process equipment. Professor Walas, drawing up on his many years of experience in industry and academia, provides a wealth of valuable shortcut methods, As China’s largest integrated refinery, Sinopec’s Zhenhai Refining & Chemical Co. (ZRCC) plant can process approximately 23 MM metric tpy of crude oil. The plant produces more than 50 fuel and chemical products, including different grades of gasoline, jet and diesel fuels, asphalt and polypropylene plastics, as well as more than 1 MM metric

This international journal covers the application of control theory, operations research, computer science and engineering principles to the solution of process control problems. This chapter describes new chemical process economic analysis methods, including the concept of chemical process analysis and basic cost items, bridging between economic analysis methods and process representation methods, which consists of the classification of process function and plant function, and mapping between them.

designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a … Process equipment designers, manufacturers and operators are challenged daily to transfer, mix, separate, heat, distill, combust, react, store, package and extend the life of the nearly 70,000 products that the chemical and processing industries provide.

Chemical Process Equipment is a guide to the selection and design of a wide range of chemical process equipment. Professor Walas, drawing up on his many years of experience in industry and academia, provides a wealth of valuable shortcut methods, 04/06/2014 · Also, it provides the true economic advantage (∆IRR between Process 1 and Process 2) when the economic evaluation is conducted at a constant feed rate. In many cases, upstream process conditions restrict the feed supply; however, even for an unconstrained feed supply, a constant feed basis still is preferable because it puts all process schemes (or projects) on the same basis and eliminates any biases due to project …