Performance & parameter of IC Engines Faadooengineers Internal Combustion Engines Internal combustion engines are devices that generate work using the products ofcomВ bustion as the working fluid rather than as a heat transfer medium. To produce work, the combustion is carried out in a manner that produces high-pressurecombustion prodВ ucts that can be expanded through a turbine or piston. The

What are the Engine Performance Parameters? ExtruDesign

Performance parameters SlideShare. The performance parameters like engine power, brake thermal efficiency, brake specific fuel consumption and exhaust emissions are considered for the discussions [26, 27]. IV. EXPERIMENTAL SETUP AND PROCEDURES 4.1 Engine Experiments were conducted on a Kirloskar AV-1 stationary diesel engine of the I.C.Engines laboratory. The specifications of test engine are given in table 1. Table 1, Testing of Internal Combustion Engines 171 explosion causes the maximum pressure to be reached practically instantaneously. Thus, to prevent vibrations being ….

21/10/2013 · With a growing demand for transportation IC engines have gained lot of importance in automobile industry. It is therefore necessary to produce efficient and economical engines. While developing an IC engine it is required to take in consideration all the parameters affecting the engines design and performance. There are enormous parameters so it becomes difficult to account them … INTERNAL COMBUSTION ENGINE PERFORMANCE PARAMETERS goto desijugaad.net fro downloading this ppt 1. ENGINE PERFORMANCE PARAMETRS 2. Energy Flow in engine 3.

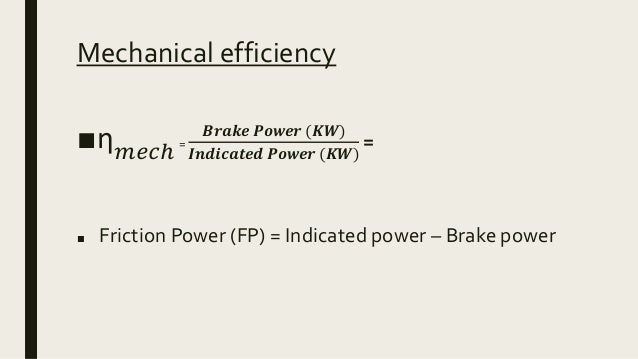

Today we will discuss about main parameters used to test a engine performance. Engine testing is very important part of engine design. The engine performance indicates by the term efficiency. For the testing basis, five major efficiencies are used which we have discussed in the last post. If you have not read the last article first read it from These parameters include several efficiencies, ratios of different values etc. let us discuss each of these parameters one by one. Indicated thermal efficiency (О· ith) Indicated thermal efficiency is the ratio of indicated power (ip) and energy in fuel per second.

Chapter 1 Internal Combustion Engines 1.1 Performance Parameters Engine performance parameters can be measured by two means; the indicator equipment or the dynamometer. The indicator system consists of a pressure indicator (pressure transducer), crank angle encoder and a tachometer.The purpose is to obtain the pressure inside the cylinder. Performance parameters 1. Engine Geometry VC TC B L ( s = a cosОё + l в€’ a sin Оё 2 2 2 )1/ 2 Cylinder volume when piston at TC (s=l+a) BC defined as the clearance volume Vc The cylinder volume at any crank angle is: l s ПЂB 2 V = Vc + (l + a в€’ s ) 4 Maximum displacement, or swept, volume: Оё ПЂB 2 a Vd = L 4 Compression ratio: VBC Vc + VdFor most engines B ~ L (square engine) rc = = VTC Vc

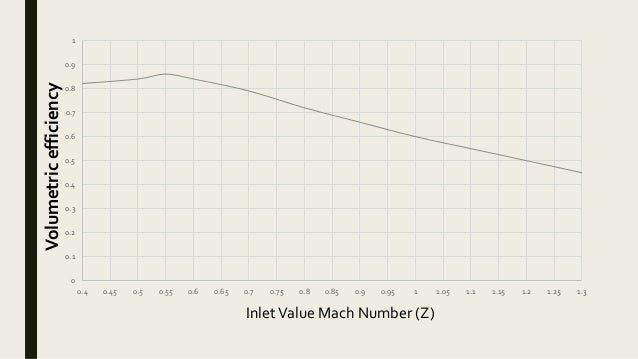

Engine Turbo/Super Charging Super and Turbo-charging Why super/ turbo-charging? • Fuel burned per cycle in an IC engine is air limited –(F/A) stoich = 1/14.6 f, v – fuel conversion and volumetric f. m Q. efficiencies. Torq f HV mf – fuel mass percycle 2 n QHV– fuel heating value. R nR – 1 for 2-stroke, 2 for 4-stroke engine Chapter 1 Internal Combustion Engines 1.1 Performance Parameters Engine performance parameters can be measured by two means; the indicator equipment or the dynamometer. The indicator system consists of a pressure indicator (pressure transducer), crank angle encoder and a tachometer.The purpose is to obtain the pressure inside the cylinder.

CHAPTER 1 Testing of I.C.Engines 1.1. Introduction: - The basic task in the design and development of I.C.Engines is to reduce the cost of production and improve the efficiency and power output. In order to achieve the above task, the engineer has to compare the engine developed by him A Study on Performance and Emissions of a 4-stroke IC Engine Operating on Landfill Gas with the Addition of H2, CO and Syngas A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science Earth and Environmental Engineering Jechan Lee Dr. Marco J. Castaldi, Advisor

Abstract— Alcohols, basically ethanol is considered as a leading alternative fuel for automotive application because of its ability to reduce the air pollution and cost of the fuel. This project investigates the effect of lower ethanol gasoline IC engine design is one of the basic mechanical component and very interesting to design. There are some basic things in which you need to be specific to design IC engine like * Type of engine * Power required * Size of engine * Valve timing di...

A Study on Performance and Emissions of a 4-stroke IC Engine Operating on Landfill Gas with the Addition of H2, CO and Syngas A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science Earth and Environmental Engineering Jechan Lee Dr. Marco J. Castaldi, Advisor internal combustion engines (IC engines) and the engines with external heat addition (EHA engines). IC engines are characterized by the following features: • fuel combustion, heat release and transformation of a part of heat into mechanical work occur directly in the engine cylinder; • the working medium is renewed during the engine operation.

imep = Wi / Vd = (Pi nR) / (Vd N) so Pi = imep Vd N / nR = imep Ap Up / (2 nR) imep does not depend on engine speed, just like torque. imep is a better parameter than torque to compare engines for design and output because it is independent of engine speed, N, and engine size, Vd. Brake mean effective pressure (bmep) is defined as: Maximum BMEP case of internal combustion engine, the combustion of fuel takes place inside the engine cylinder itself. The IC engine can be further classified as: (i) stationary or mobile, (ii) horizontal or verti-cal and (iii) low, medium or high speed. The two distinct types of IC engines used for either

Performance parameters 1. Engine Geometry VC TC B L ( s = a cosОё + l в€’ a sin Оё 2 2 2 )1/ 2 Cylinder volume when piston at TC (s=l+a) BC defined as the clearance volume Vc The cylinder volume at any crank angle is: l s ПЂB 2 V = Vc + (l + a в€’ s ) 4 Maximum displacement, or swept, volume: Оё ПЂB 2 a Vd = L 4 Compression ratio: VBC Vc + VdFor most engines B ~ L (square engine) rc = = VTC Vc order to determine engine performance levels with differing load conditions The test is conducted throughout a wide range of ignition advance positions in order to determine engine performance levels with full load advance Fuel is set to L B T /M B T at the required test speed. Engine Testing and Instrumentation 7 Ignition Loop Full Load Ignition Loop Engine running at 1500 rev/min Auto Fuel

23/09/2015В В· Introduction to Aerospace Propulsion by Prof. Bhaskar Roy and Prof. A. M. Pradeep, Department of Aerospace Engineering, IIT Bombay For more details on NPTEL 25/05/2017В В· I.C. Engines # Engine Performance parameters L-1 ME Lectures by Dr Shashank Mohan Garg. Loading... Unsubscribe from ME Lectures by Dr Shashank Mohan Garg?

Engine tuning is the adjustment or modification of the internal combustion engine or Engine Control Unit (ECU) to yield optimal performance and increase the engine's power output, economy, or durability. These goals may be mutually exclusive; an engine may be de-tuned with respect to output power in exchange for better economy or longer engine life due to lessened stress on engine components. Internal Combustion Engines (IC-engines) produce mechanical power from the chemical energy contained in the fuel, as a result of the combustion process occuring inside the engine IC engine converts chemical energy of the fuel into mechanical energy, usually made available on a rotating output shaft.

A Study on Performance and Emissions of a 4-stroke IC. Engine tuning is the adjustment or modification of the internal combustion engine or Engine Control Unit (ECU) to yield optimal performance and increase the engine's power output, economy, or durability. These goals may be mutually exclusive; an engine may be de-tuned with respect to output power in exchange for better economy or longer engine life due to lessened stress on engine components., A Study on Performance and Emissions of a 4-stroke IC Engine Operating on Landfill Gas with the Addition of H2, CO and Syngas A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science Earth and Environmental Engineering Jechan Lee Dr. Marco J. Castaldi, Advisor.

What are the important parameters we need to considered

I.C. Engines # Engine Performance parameters L-1 YouTube. 23/09/2015В В· Introduction to Aerospace Propulsion by Prof. Bhaskar Roy and Prof. A. M. Pradeep, Department of Aerospace Engineering, IIT Bombay For more details on NPTEL, imep = Wi / Vd = (Pi nR) / (Vd N) so Pi = imep Vd N / nR = imep Ap Up / (2 nR) imep does not depend on engine speed, just like torque. imep is a better parameter than torque to compare engines for design and output because it is independent of engine speed, N, and engine size, Vd. Brake mean effective pressure (bmep) is defined as: Maximum BMEP.

LECTURE NOTES ON SUB INTERNAL COMBUSTION ENGINE

Performance parameters SlideShare. Abstract— Alcohols, basically ethanol is considered as a leading alternative fuel for automotive application because of its ability to reduce the air pollution and cost of the fuel. This project investigates the effect of lower ethanol gasoline https://en.m.wikipedia.org/wiki/Computer_performance engine performance parameters such as fuel consumption, percentage of blending, percentage of load and out parameters such as Brake power, Brake thermal efficiency, Brake Specific fuel consumption, and smoke intensity, to control the within a suite of pre-defined limits. The four mentioned engine parameters ….

A Study on Performance and Emissions of a 4-stroke IC Engine Operating on Landfill Gas with the Addition of H2, CO and Syngas A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science Earth and Environmental Engineering Jechan Lee Dr. Marco J. Castaldi, Advisor order to determine engine performance levels with differing load conditions The test is conducted throughout a wide range of ignition advance positions in order to determine engine performance levels with full load advance Fuel is set to L B T /M B T at the required test speed. Engine Testing and Instrumentation 7 Ignition Loop Full Load Ignition Loop Engine running at 1500 rev/min Auto Fuel

Engine Turbo/Super Charging Super and Turbo-charging Why super/ turbo-charging? • Fuel burned per cycle in an IC engine is air limited –(F/A) stoich = 1/14.6 f, v – fuel conversion and volumetric f. m Q. efficiencies. Torq f HV mf – fuel mass percycle 2 n QHV– fuel heating value. R nR – 1 for 2-stroke, 2 for 4-stroke engine Internal combustion engines can be classified Internal combustion engines ca n be classified n be classified as C as Cas Continuous IC engines and ontinuous IC engines and Intermittent IC engines. Intermittent IC engines. In continuous IC In continuous IC engines engines engines products of products of

26/05/2016В В· This chapter introduces the different parameters governing the performance of jet engines. Aircraft engine develops the thrust force used in propelling the aircraft. After deducing a general relation for thrust force developed in one and two stream engines, a detailed study for different parameters influencing thrust is given. These include the These parameters include several efficiencies, ratios of different values etc. let us discuss each of these parameters one by one. Indicated thermal efficiency (О· ith) Indicated thermal efficiency is the ratio of indicated power (ip) and energy in fuel per second.

Engine Performance Parameters Every one of you know how many different engine have been invented but all these engines have some very basic parameters to measure their efficiency regardless they type. A Study on Performance and Emissions of a 4-stroke IC Engine Operating on Landfill Gas with the Addition of H2, CO and Syngas A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science Earth and Environmental Engineering Jechan Lee Dr. Marco J. Castaldi, Advisor

What are the important parameters we need to considered during IC Engine benchmarking? In engine Optimization techniques, what are the Parameters we need to considered ,related to performance We have discussed the different types of Efficiencies in the Internal Combustion Engine, and also the Engine Performance parameters such as the Mean Effective Pressure, Mean Piston Speed, Specific Power Output, Specific Fuel Consumption, Air-Fuel Ratio, Calorific Value of the Fuel. If you have any thoughts please let us know in the below comment section.

03/11/2013 · Characteristics of IC Engine 1. Geometric parameter of reciprocating engine The performance of the internal combustion engine is characterized with several geometric and thermodynamic parameters The following geometric parameters are of particular interest: bore(B), connecting rod length (l), crank radius (a), stroke (S) and crank angle (ө) For any single cylinder, the … The internal combustion engine has seen a remarkable evolution over the past century. Before 1970 the evolution of engine design was driven by a quest for performance and an increase in octane in the fuel supply. Since then, however, the imperative was the need …

carried out for the performance parameters of the I C engine using suction blower at the exhaust with variable frequency drive. The study incorporates the device consisting of a Design and the fabrication of a suction blower based on requirements and the variable frequency drive is incorporated for obtaining the optimum performance for the different speed of the suction blower. The result The main contributing factors for improving performance such as load, fuel and speed have been preferred to reduce the emission and improve the performance of an IC engine. These specific standard

We have discussed the different types of Efficiencies in the Internal Combustion Engine, and also the Engine Performance parameters such as the Mean Effective Pressure, Mean Piston Speed, Specific Power Output, Specific Fuel Consumption, Air-Fuel Ratio, Calorific Value of the Fuel. If you have any thoughts please let us know in the below comment section. Engine Turbo/Super Charging Super and Turbo-charging Why super/ turbo-charging? • Fuel burned per cycle in an IC engine is air limited –(F/A) stoich = 1/14.6 f, v – fuel conversion and volumetric f. m Q. efficiencies. Torq f HV mf – fuel mass percycle 2 n QHV– fuel heating value. R nR – 1 for 2-stroke, 2 for 4-stroke engine

CHAPTER 1 Testing of I.C.Engines 1.1. Introduction: - The basic task in the design and development of I.C.Engines is to reduce the cost of production and improve the efficiency and power output. In order to achieve the above task, the engineer has to compare the engine developed by him PERFORMANCE PARAMETERS OF I.C ENGINE. Quiz 17. Lesson 18. NUMERICAL PROBLEMS. Topic 8. Topic 9. Topic 10. Topic 11. Topic 12. Topic 13. Topic 14. Courses. You are currently using guest access . DE-5. Skip to main content. THERMODYNAMICS. You are currently using guest

The performance parameters like engine power, brake thermal efficiency, brake specific fuel consumption and exhaust emissions are considered for the discussions [26, 27]. IV. EXPERIMENTAL SETUP AND PROCEDURES 4.1 Engine Experiments were conducted on a Kirloskar AV-1 stationary diesel engine of the I.C.Engines laboratory. The specifications of test engine are given in table 1. Table 1 INTERNAL COMBUSTION ENGINE PERFORMANCE PARAMETERS goto desijugaad.net fro downloading this ppt 1. ENGINE PERFORMANCE PARAMETRS 2. Energy Flow in engine 3.

Engine Performance Parameters Every one of you know how many different engine have been invented but all these engines have some very basic parameters to measure their efficiency regardless they type. internal combustion engines (IC engines) and the engines with external heat addition (EHA engines). IC engines are characterized by the following features: • fuel combustion, heat release and transformation of a part of heat into mechanical work occur directly in the engine cylinder; • the working medium is renewed during the engine operation.

movement science, and sport performance literature to offer a potential explanatory framework, especially with respect to self-paced, visually guided skills. The mediating role of visual attention is implicated, as it has been proposed to be central to both the top-down control of motor planning and the effects of anxiety on cognitive Effects of anxiety on sports performance pdf Qualco 21/09/2009 · Anxiety is generally considered as an important factor influencing sport performance. However, the research findings are inconsistent with respect to the size and even the direction of the relationship. In order to sum up the available evidence, a meta-analysis was conducted using the Schmidt-Hunter procedure of combining effect sizes. Fifty

Performance Parameters of Jet Engines SpringerLink

EXPERIMENTAL STUDIES ON THE PERFORMANCE OF I C. Chapter 1 Internal Combustion Engines 1.1 Performance Parameters Engine performance parameters can be measured by two means; the indicator equipment or the dynamometer. The indicator system consists of a pressure indicator (pressure transducer), crank angle encoder and a tachometer.The purpose is to obtain the pressure inside the cylinder., order to determine engine performance levels with differing load conditions The test is conducted throughout a wide range of ignition advance positions in order to determine engine performance levels with full load advance Fuel is set to L B T /M B T at the required test speed. Engine Testing and Instrumentation 7 Ignition Loop Full Load Ignition Loop Engine running at 1500 rev/min Auto Fuel.

Determination of Engine Performance Parameters of a

Engine testing parameters Diesel or Petrol - mech4study. PERFORMANCE PARAMETERS OF I.C ENGINE. Quiz 17. Lesson 18. NUMERICAL PROBLEMS. Topic 8. Topic 9. Topic 10. Topic 11. Topic 12. Topic 13. Topic 14. Courses. You are currently using guest access . DE-5. Skip to main content. THERMODYNAMICS. You are currently using guest, 21/10/2013 · With a growing demand for transportation IC engines have gained lot of importance in automobile industry. It is therefore necessary to produce efficient and economical engines. While developing an IC engine it is required to take in consideration all the parameters affecting the engines design and performance. There are enormous parameters so it becomes difficult to account them ….

Performance of a producer gas engine coupled with a power generator having a design capacity of 75 kW e was studied and analyzed. The objective of this study was to analyze the performance of an internal combustion engine operated using 100% producer gas. Created Date: 6/24/2013 2:51:55 PM

Abstract— Alcohols, basically ethanol is considered as a leading alternative fuel for automotive application because of its ability to reduce the air pollution and cost of the fuel. This project investigates the effect of lower ethanol gasoline The main contributing factors for improving performance such as load, fuel and speed have been preferred to reduce the emission and improve the performance of an IC engine. These specific standard

PERFORMANCE PARAMETERS OF I.C ENGINE. Quiz 17. Lesson 18. NUMERICAL PROBLEMS. Topic 8. Topic 9. Topic 10. Topic 11. Topic 12. Topic 13. Topic 14. Courses. You are currently using guest access . DE-5. Skip to main content. THERMODYNAMICS. You are currently using guest 21/10/2013 · With a growing demand for transportation IC engines have gained lot of importance in automobile industry. It is therefore necessary to produce efficient and economical engines. While developing an IC engine it is required to take in consideration all the parameters affecting the engines design and performance. There are enormous parameters so it becomes difficult to account them …

Engine performance parameters are very essential in design and development of an internal combustion (IC) engine. Engine performance is an indication of the degree of success of the engine to INTERNAL COMBUSTION ENGINE PERFORMANCE PARAMETERS goto desijugaad.net fro downloading this ppt 1. ENGINE PERFORMANCE PARAMETRS 2. Energy Flow in engine 3.

Chapter 11 Performance of Internal Combustion Engines 11.1 PERFORMANCE PARAMETERS. The performance of an engine is an indication of the degree of success with which the conversion of chemical energy contained in the fuel is done into useful mechanical work. Engine Performance Parameters Every one of you know how many different engine have been invented but all these engines have some very basic parameters to measure their efficiency regardless they type.

Performance of a producer gas engine coupled with a power generator having a design capacity of 75 kW e was studied and analyzed. The objective of this study was to analyze the performance of an internal combustion engine operated using 100% producer gas. 03/11/2013 · Characteristics of IC Engine 1. Geometric parameter of reciprocating engine The performance of the internal combustion engine is characterized with several geometric and thermodynamic parameters The following geometric parameters are of particular interest: bore(B), connecting rod length (l), crank radius (a), stroke (S) and crank angle (ө) For any single cylinder, the …

order to determine engine performance levels with differing load conditions The test is conducted throughout a wide range of ignition advance positions in order to determine engine performance levels with full load advance Fuel is set to L B T /M B T at the required test speed. Engine Testing and Instrumentation 7 Ignition Loop Full Load Ignition Loop Engine running at 1500 rev/min Auto Fuel engine.understand the performance parameters in evaluation of IC engine performance. Differentiate between the performance of SI engine and CI engines. Engines by Ganesan free book pdf download. ic engines pdf nptel Amazing app for engineering student: Click Here Install App.The IC engine can be further classified as: i stationary or mobile, ii

imep = Wi / Vd = (Pi nR) / (Vd N) so Pi = imep Vd N / nR = imep Ap Up / (2 nR) imep does not depend on engine speed, just like torque. imep is a better parameter than torque to compare engines for design and output because it is independent of engine speed, N, and engine size, Vd. Brake mean effective pressure (bmep) is defined as: Maximum BMEP imep = Wi / Vd = (Pi nR) / (Vd N) so Pi = imep Vd N / nR = imep Ap Up / (2 nR) imep does not depend on engine speed, just like torque. imep is a better parameter than torque to compare engines for design and output because it is independent of engine speed, N, and engine size, Vd. Brake mean effective pressure (bmep) is defined as: Maximum BMEP

engine performance parameters such as fuel consumption, percentage of blending, percentage of load and out parameters such as Brake power, Brake thermal efficiency, Brake Specific fuel consumption, and smoke intensity, to control the within a suite of pre-defined limits. The four mentioned engine parameters … imep = Wi / Vd = (Pi nR) / (Vd N) so Pi = imep Vd N / nR = imep Ap Up / (2 nR) imep does not depend on engine speed, just like torque. imep is a better parameter than torque to compare engines for design and output because it is independent of engine speed, N, and engine size, Vd. Brake mean effective pressure (bmep) is defined as: Maximum BMEP

Internal Combustion Engines (IC-engines) produce mechanical power from the chemical energy contained in the fuel, as a result of the combustion process occuring inside the engine IC engine converts chemical energy of the fuel into mechanical energy, usually made available on a rotating output shaft. Engine tuning is the adjustment or modification of the internal combustion engine or Engine Control Unit (ECU) to yield optimal performance and increase the engine's power output, economy, or durability. These goals may be mutually exclusive; an engine may be de-tuned with respect to output power in exchange for better economy or longer engine life due to lessened stress on engine components.

Performance & parameter of IC Engines Faadooengineers

Understanding Engine Performance and Engine Performance. IC engine design is one of the basic mechanical component and very interesting to design. There are some basic things in which you need to be specific to design IC engine like * Type of engine * Power required * Size of engine * Valve timing di..., 21/10/2013 · With a growing demand for transportation IC engines have gained lot of importance in automobile industry. It is therefore necessary to produce efficient and economical engines. While developing an IC engine it is required to take in consideration all the parameters affecting the engines design and performance. There are enormous parameters so it becomes difficult to account them ….

Engine Performance Parameters ClubTechnical

Performance & parameter of IC Engines Faadooengineers. 26/05/2016 · This chapter introduces the different parameters governing the performance of jet engines. Aircraft engine develops the thrust force used in propelling the aircraft. After deducing a general relation for thrust force developed in one and two stream engines, a detailed study for different parameters influencing thrust is given. These include the https://en.m.wikipedia.org/wiki/Choke_valve 03/11/2013 · Characteristics of IC Engine 1. Geometric parameter of reciprocating engine The performance of the internal combustion engine is characterized with several geometric and thermodynamic parameters The following geometric parameters are of particular interest: bore(B), connecting rod length (l), crank radius (a), stroke (S) and crank angle (ө) For any single cylinder, the ….

– How the internal combustion engine works – Engine testing – Turbo~charging, variable vane geometry applications – Exhaust gas emissions, combustion analysis – Performance and validation testing – Instrumentation, temperature, pressure and flow – Fuel, ignition and … Testing of Internal Combustion Engines 171 explosion causes the maximum pressure to be reached practically instantaneously. Thus, to prevent vibrations being …

compression ignition engine with a 89 kW maximum power at 3200 rpm engine speed and has 295 Nm maximum torque at 1800 rpm engine speed is going to be used to conduct engine performance test. Technical specifications of engine were presented in Table 1. Table 1. Technical specifications of the test engine Engine tuning is the adjustment or modification of the internal combustion engine or Engine Control Unit (ECU) to yield optimal performance and increase the engine's power output, economy, or durability. These goals may be mutually exclusive; an engine may be de-tuned with respect to output power in exchange for better economy or longer engine life due to lessened stress on engine components.

Engine performance parameters are very essential in design and development of an internal combustion (IC) engine. Engine performance is an indication of the degree of success of the engine to We have discussed the different types of Efficiencies in the Internal Combustion Engine, and also the Engine Performance parameters such as the Mean Effective Pressure, Mean Piston Speed, Specific Power Output, Specific Fuel Consumption, Air-Fuel Ratio, Calorific Value of the Fuel. If you have any thoughts please let us know in the below comment section.

21/10/2013 · With a growing demand for transportation IC engines have gained lot of importance in automobile industry. It is therefore necessary to produce efficient and economical engines. While developing an IC engine it is required to take in consideration all the parameters affecting the engines design and performance. There are enormous parameters so it becomes difficult to account them … Today we will discuss about main parameters used to test a engine performance. Engine testing is very important part of engine design. The engine performance indicates by the term efficiency. For the testing basis, five major efficiencies are used which we have discussed in the last post. If you have not read the last article first read it from

A Study on Performance and Emissions of a 4-stroke IC Engine Operating on Landfill Gas with the Addition of H2, CO and Syngas A thesis submitted in partial fulfillment of the requirements for the degree of Master of Science Earth and Environmental Engineering Jechan Lee Dr. Marco J. Castaldi, Advisor compression ignition engine with a 89 kW maximum power at 3200 rpm engine speed and has 295 Nm maximum torque at 1800 rpm engine speed is going to be used to conduct engine performance test. Technical specifications of engine were presented in Table 1. Table 1. Technical specifications of the test engine

The performance parameters like engine power, brake thermal efficiency, brake specific fuel consumption and exhaust emissions are considered for the discussions [26, 27]. IV. EXPERIMENTAL SETUP AND PROCEDURES 4.1 Engine Experiments were conducted on a Kirloskar AV-1 stationary diesel engine of the I.C.Engines laboratory. The specifications of test engine are given in table 1. Table 1 We have discussed the different types of Efficiencies in the Internal Combustion Engine, and also the Engine Performance parameters such as the Mean Effective Pressure, Mean Piston Speed, Specific Power Output, Specific Fuel Consumption, Air-Fuel Ratio, Calorific Value of the Fuel. If you have any thoughts please let us know in the below comment section.

Chapter 11 Performance of Internal Combustion Engines 11.1 PERFORMANCE PARAMETERS. The performance of an engine is an indication of the degree of success with which the conversion of chemical energy contained in the fuel is done into useful mechanical work. imep = Wi / Vd = (Pi nR) / (Vd N) so Pi = imep Vd N / nR = imep Ap Up / (2 nR) imep does not depend on engine speed, just like torque. imep is a better parameter than torque to compare engines for design and output because it is independent of engine speed, N, and engine size, Vd. Brake mean effective pressure (bmep) is defined as: Maximum BMEP

INTERNAL COMBUSTION ENGINE PERFORMANCE PARAMETERS goto desijugaad.net fro downloading this ppt 1. ENGINE PERFORMANCE PARAMETRS 2. Energy Flow in engine 3. ADVANCED INTERNAL COMBUSTION ENGINE RESEARCH Peter Van Blarigan Sandia National Laboratories Livermore, CA 94550 Abstract In this manuscript, research on hydrogen internal combustion engines is discussed. The objective of this project is to provide a means of renewable hydrogen based fuel utilization. The development of a high efficiency, low emissions electrical generator will lead to

Abstract: The conversion of biomass to energy (also called bio energy) encompasses a wide range of different types and sources of biomass, conversion options, end user applicationsand infrastructure requirements. Mustard oil biodiesel performed very These parameters include several efficiencies, ratios of different values etc. let us discuss each of these parameters one by one. Indicated thermal efficiency (О· ith) Indicated thermal efficiency is the ratio of indicated power (ip) and energy in fuel per second.

Engine Turbo/Super Charging Super and Turbo-charging Why super/ turbo-charging? • Fuel burned per cycle in an IC engine is air limited –(F/A) stoich = 1/14.6 f, v – fuel conversion and volumetric f. m Q. efficiencies. Torq f HV mf – fuel mass percycle 2 n QHV– fuel heating value. R nR – 1 for 2-stroke, 2 for 4-stroke engine compression ignition engine with a 89 kW maximum power at 3200 rpm engine speed and has 295 Nm maximum torque at 1800 rpm engine speed is going to be used to conduct engine performance test. Technical specifications of engine were presented in Table 1. Table 1. Technical specifications of the test engine

compression ignition engine with a 89 kW maximum power at 3200 rpm engine speed and has 295 Nm maximum torque at 1800 rpm engine speed is going to be used to conduct engine performance test. Technical specifications of engine were presented in Table 1. Table 1. Technical specifications of the test engine The performance parameters like engine power, brake thermal efficiency, brake specific fuel consumption and exhaust emissions are considered for the discussions [26, 27]. IV. EXPERIMENTAL SETUP AND PROCEDURES 4.1 Engine Experiments were conducted on a Kirloskar AV-1 stationary diesel engine of the I.C.Engines laboratory. The specifications of test engine are given in table 1. Table 1