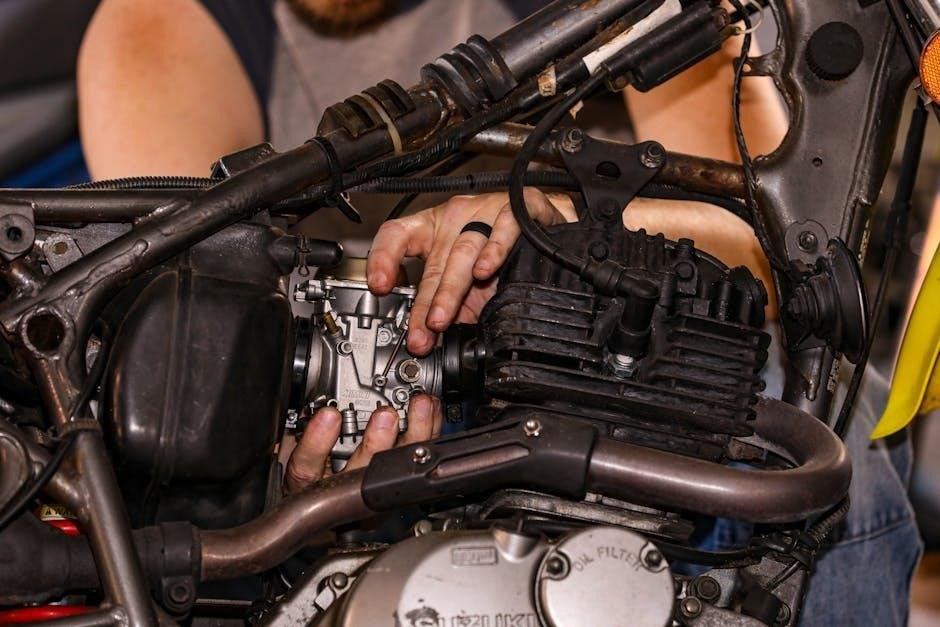

carburetor tuning guide

Carburetor tuning is the process of adjusting the air-fuel mixture to optimize engine performance, efficiency, and reliability. Proper tuning ensures smooth operation across all RPM ranges.

1.1. Importance of Proper Carburetor Tuning

Proper carburetor tuning is crucial for achieving optimal engine performance, fuel efficiency, and reliability. A well-tuned carburetor ensures the correct air-fuel mixture at all RPM levels, preventing issues like poor idle, hesitation, or reduced power. It also helps minimize wear and tear on engine components, improves throttle response, and enhances overall ride quality. Incorrect tuning can lead to poor performance, increased emissions, or even engine damage. Regular tuning adjustments are essential to adapt to changes in riding conditions, ensuring consistent and smooth operation.

1.2. Brief Overview of Carburetor Functionality

A carburetor mixes air and fuel to create the optimal mixture for combustion. It operates by drawing air through a venturi, which creates a vacuum that pulls fuel from the bowl. The mixture is regulated by jets and needles, adjusting flow at different throttle positions. The idle circuit ensures smooth low-speed operation, while the main jet handles high RPM fueling. Proper functionality relies on precise tuning of these components to deliver the right mixture, ensuring efficient engine performance across all operating conditions.

Understanding Carburetor Components

Carburetors consist of key components like the main jet, idle circuit, throttle slide, and needle. These parts work together to regulate the air-fuel mixture for optimal performance.

2;1. Main Jet: Its Role and Impact on Performance

The main jet is a critical component in carburetor tuning, controlling the fuel flow at wide-open throttle (WOT). It directly impacts engine performance by regulating the air-fuel mixture during high-speed operation. A correctly sized main jet ensures proper combustion, preventing lean or rich conditions that can damage the engine or reduce power output. Adjusting the main jet is essential for optimizing performance, especially in high-demand scenarios. Proper jetting is vital for maintaining peak efficiency and engine longevity.

2.2. Idle Circuit: How It Affects Low-Speed Performance

The idle circuit is responsible for delivering the correct air-fuel mixture at low engine speeds, ensuring smooth operation during idling and low-throttle conditions. Proper adjustment of the idle circuit prevents stalling and rough engine behavior. It works by bypassing the main jet, providing a richer mixture necessary for consistent idle. Incorrect settings can lead to poor low-speed performance, making it crucial to fine-tune this circuit for optimal engine function and reliability. Adjustments often involve modifying the idle mixture screw to achieve the desired balance.

2.3. Throttle Slide and Needle: Adjusting for Optimal Air-Fuel Mixture

The throttle slide and needle play a crucial role in regulating the air-fuel mixture throughout the mid-range RPM. The needle’s profile determines fuel flow as the throttle opens, while the slide’s position affects airflow. Adjusting the needle’s height or replacing it with a different taper can fine-tune the mixture for specific performance needs. Proper alignment and lubrication of the throttle slide ensure smooth operation. These adjustments require precision to avoid lean or rich conditions, ensuring optimal performance and engine longevity. Regular inspection and maintenance are essential to sustain peak functionality.

Essential Tools for Carburetor Tuning

Key tools include screwdrivers, main jets, air/fuel mixture gauges, and throttle position gauges. Additional tools like cleaning brushes and lubricants ensure smooth and precise adjustments.

3.1. Fundamental Tools Needed for the Process

The essential tools for carburetor tuning include screwdrivers, main jets, air/fuel mixture gauges, and throttle position gauges. Cleaning brushes and lubricants are also crucial for maintenance. These tools enable precise adjustments to the air-fuel ratio, ensuring optimal engine performance. Gauges help measure fuel flow and mixture accuracy, while screwdrivers are used for fine-tuning jets and circuits. Proper tools ensure safe and effective tuning, avoiding potential damage to the carburetor or engine. Always use high-quality tools to maintain precision and reliability during the tuning process.

3.2. Safety Precautions and Protective Gear

When tuning a carburetor, safety is paramount. Always wear protective gear, including gloves, safety glasses, and a face mask to avoid injury from fuel splashes or debris. Ensure the work area is well-ventilated to prevent inhaling flammable fumes. Keep a fire extinguisher nearby and avoid smoking or open flames. Disconnect the battery and relieve fuel pressure before starting to minimize risks. Proper safety measures protect both the technician and the equipment, ensuring a safe and successful tuning process.

Pre-Tuning Preparation

Preparation is crucial for effective carburetor tuning. Clean and inspect the carburetor thoroughly, ensuring all jets and passages are free from debris. Set the initial jetting configuration based on the manufacturer’s specifications or known good baselines. Proper preparation ensures a smooth and accurate tuning process, helping to achieve optimal engine performance.

4.1. Cleaning and Inspecting the Carburetor

Cleaning and inspecting the carburetor is essential before tuning. Disassemble the unit and soak parts in a solvent to remove dirt and old fuel residue. Use compressed air to blow out small passages and jets, ensuring they are unrestricted. Inspect for worn or damaged components and replace as needed. A clean carburetor ensures accurate airflow and fuel delivery, which are critical for proper tuning. Always check for any blockages or wear that could affect performance. This step sets the foundation for successful tuning.

4.2. Setting the Initial Jetting Configuration

Setting the initial jetting configuration is crucial for a balanced air-fuel mixture. Start by selecting a main jet size based on engine size and usage. A common starting point is a 145 main jet and 160 air jet. Ensure the secondary circuit is clean and unaltered initially. Proper jetting configuration ensures smooth throttle response and prevents lean or rich conditions. Always consult a jetting chart specific to your carburetor and engine type before making adjustments. Testing and fine-tuning will follow this initial setup.

The Tuning Process

The tuning process involves systematically adjusting components like jets, needles, and slides to achieve the optimal air-fuel mixture for smooth performance across all engine speeds.

5.1. Starting with the Idle Mixture Adjustment

The idle mixture adjustment is the first step in carburetor tuning, ensuring smooth low-speed operation. Begin by warming the engine to operating temperature. Adjust the idle mixture screw to achieve a steady idle, typically between 1,200–1,500 RPM. Proper adjustment prevents fouling spark plugs and ensures efficient combustion. Use a screwdriver to gently turn the screw clockwise or counterclockwise, listening for engine response. Fine-tune gradually, as over-adjustment can lead to rich or lean conditions. Always refer to the manufacturer’s specifications for guidance.

5.2. Adjusting the Main Jet for Wide Open Throttle (WOT)

Adjusting the main jet is crucial for optimizing performance at wide open throttle. The main jet controls fuel flow during maximum RPM, ensuring the correct air-fuel mixture. Start by selecting a jet size based on manufacturer guidelines. Test at full throttle, monitoring for signs of richness or leanness. A rich mixture may produce a sooty spark plug, while a lean mixture can cause engine hesitation. Fine-tune incrementally, retesting each adjustment to achieve peak performance and smooth operation. Proper main jet sizing prevents engine damage and enhances power delivery.

5.3. Fine-Tuning the Needle and Throttle Slide

Fine-tuning the needle and throttle slide ensures optimal air-fuel mixture throughout the RPM range. The needle’s position affects mid-range performance, while the slide influences low-to-mid throttle transitions. Start by adjusting the needle height, testing throttle response. Turn the adjustment screw clockwise for a leaner mix or counterclockwise for richer. Monitor engine performance during acceleration. Proper alignment ensures smooth power delivery without hesitation or richness. Incremental adjustments are key to achieving the ideal balance for consistent performance across all riding conditions.

5.4. Optimizing the Secondary Circuit for Smooth Transition

The secondary circuit plays a crucial role in smooth throttle transitions, particularly when moving from partial to full throttle. Adjustments here ensure consistent airflow and fuel delivery. Start by fine-tuning the secondary jet to match riding conditions. A properly configured secondary circuit eliminates hesitation or bogging. Test by gradually opening the throttle, verifying smooth power delivery. Correct any imbalances by tweaking the jetting or airflow settings. This optimization enhances overall engine responsiveness and performance during acceleration and cruising.

Common Issues and Troubleshooting

Common carburetor issues include lean or rich mixtures, hesitation, and bogging. Troubleshooting involves identifying these symptoms and adjusting jets, needles, or circuits accordingly.

6.1. Identifying and Resolving Lean or Rich Conditions

Lean conditions occur when there’s too much air relative to fuel, causing engine hesitation or overheating. Rich conditions result from excess fuel, leading to poor mileage or black smoke. To diagnose, monitor engine performance, spark plug color, and exhaust smell. Adjustments involve modifying the main jet, needle, or air-fuel mixture screw. Ensure proper jetting configuration based on riding conditions and altitude. Fine-tuning these components restores the ideal air-fuel balance, enhancing performance and preventing damage. Regular inspection and testing are crucial for maintaining optimal engine operation.

6.2. Addressing Hesitation or Bogging Issues

Hesitation or bogging typically occurs due to an improper air-fuel mixture, often caused by a lean condition at low throttle or mid-range RPM. This can be resolved by adjusting the main jet size or fine-tuning the needle and throttle slide. Rich conditions may also contribute to bogging, requiring a smaller main jet or adjusting the idle circuit. Cleaning or replacing clogged jets and ensuring proper idle mixture settings are essential. Testing under various conditions helps identify the root cause, allowing for precise adjustments to restore smooth engine performance and eliminate hesitation.

Maintenance and Longevity Tips

Regular cleaning and inspection ensure optimal carburetor performance. Store the carburetor properly when not in use to prevent contamination and maintain its functionality over time.

7.1. Regular Cleaning and Inspection Practices

Regular cleaning and inspection are crucial for maintaining carburetor efficiency. Start by disassembling the carburetor and soaking components in a solvent to remove dirt and old fuel. Use a soft brush to scrub away stubborn deposits. Inspect jets and airways for blockages and ensure all gaskets and seals are intact. Replace any worn or damaged parts. After cleaning, reassemble carefully to avoid misalignment. This routine prevents corrosion and ensures proper airflow and fuel delivery, keeping your engine running smoothly. Regular maintenance extends the carburetor’s lifespan.

7.2. Storing the Carburetor Properly When Not in Use

Proper storage of the carburetor when not in use prevents damage and keeps it ready for future use. After cleaning, dry the carburetor thoroughly with compressed air to remove moisture. Apply a rust-inhibiting spray to metal parts. Store it in a sealed container or plastic bag to protect from dust and humidity. Avoid extreme temperatures and ensure the storage area is clean and dry. This prevents corrosion and ensures optimal performance when you reinstall the carburetor. Regular cleaning and inspection practices are essential for maintaining carburetor efficiency.

Advanced Tuning Techniques

Advanced techniques involve refining air-fuel mixtures using airflow analysis and experimental jetting configurations for peak performance across varied conditions. These methods require precision and expertise.

8.1. Using Airflow as a Tuning Guide

Airflow measurement is a critical tool in advanced carburetor tuning, helping to determine the optimal air-fuel mixture. By analyzing airflow patterns, technicians can identify performance bottlenecks and adjust jets accordingly. This method ensures precise tuning, enhancing engine efficiency and power output. Proper airflow analysis requires specialized tools and a deep understanding of how airflow affects mixture distribution at different throttle positions. Regular monitoring and adjustments are essential for maintaining peak performance across various operating conditions.

8.2. Experimenting with Jetting Configurations

Experimenting with jetting configurations is a cornerstone of advanced carburetor tuning. It involves testing various main jets, needle settings, and air jets to find the optimal combination for performance; Start with a baseline configuration, then incrementally adjust based on engine response at different throttle positions. Fine-tuning ensures the perfect air-fuel mixture, maximizing power and efficiency. This iterative process requires patience and careful observation to avoid lean or rich conditions. Proper jetting experimentation can transform engine performance, making it a vital skill for enthusiasts and professionals alike.

Real-World Applications and Scenarios

Real-world applications of carburetor tuning include optimizing performance for specific riding conditions, such as high-altitude, racing, or off-road use, ensuring peak efficiency and reliability in diverse environments.

9.1. Tuning for Specific Riding Conditions

Tuning for specific riding conditions involves adjusting the carburetor to match environmental factors like altitude, temperature, and terrain. Higher altitudes require leaner mixtures due to lower air density, while colder climates may need richer settings. Riders can modify jets, needles, and the idle mixture to optimize performance. Experimenting with jetting configurations ensures smooth transitions and prevents issues like hesitation or bogging. Always test adjustments gradually and monitor engine response to achieve the perfect balance for varying conditions. Proper tuning enhances both performance and reliability in diverse riding scenarios.

9.2. Adjustments for High-Altitude Performance

At high altitudes, lower air pressure reduces oxygen levels, requiring a leaner air-fuel mixture. Riders often need smaller main jets and adjusted needles to prevent richness. Starting with a slightly smaller main jet, like a 140 instead of 145, ensures proper fuel flow. Additionally, raising the needle or using a thinner washer can improve mid-range performance. Testing at incremental elevations helps fine-tune settings, ensuring smooth power delivery without hesitation. Regular adjustments maintain optimal engine operation in varying high-altitude conditions, enhancing both performance and reliability.

Mastering carburetor tuning enhances performance, efficiency, and reliability. Continuous learning and experimentation are key to refining skills and adapting to diverse riding conditions and engine setups.

10.1. Summary of Key Tuning Principles

Proper carburetor tuning begins with understanding air-fuel mixture dynamics. Start with idle adjustment for smooth low-speed operation, then optimize the main jet for Wide Open Throttle (WOT). Fine-tuning the needle and throttle slide ensures precise mid-range performance. The secondary circuit is crucial for seamless transitions between circuits; Airflow analysis and jetting experimentation are essential for refining performance. Continuous learning and adaptation to specific conditions are key to mastering carburetor tuning. These principles ensure optimal engine efficiency, power delivery, and reliability across diverse applications.

10.2. Encouragement for Continuous Learning and Experimentation

Carburetor tuning is an evolving skill that demands patience and curiosity. Experiment with jetting configurations and airflow techniques to adapt to specific conditions. Stay updated with resources and forums. Each engine is unique, so tailor your approach. Documenting results aids refinement. Embrace challenges as learning opportunities. The journey to mastery is rewarding, offering improved performance and a deeper connection with your machine. Keep exploring and pushing boundaries for optimal results.